We here at AION, since its founding in 1999, have held up "Harmonization with society and environment: Foster a spirit of appreciating people and cherishing the environment" as one of our operating principles. In response to the tendency worldwide toward deepening environmental problems, and grounded in our own operating principles, we have endeavored toward business activities whose burden on the planet is minimal: In 2006 we acquired ISO 14000 series (environmental management system) certification, and in 2015 we replaced our fuel-oil boiler for producing steam with an environmentally friendly gas boiler of lower CO2 emissions. We have also endeavored to conserve the aquatic environment by installing intelligent wastewater treatment facilities, and to curtail toxic-substance emission volume by putting into place a high-performance industrial waste incinerator installation.

And here at the company itself, we are moving forward with commitments aimed at making products and providing services—including our PVA Microbe Carrier and our solid–liquid separating device, the PC Separator, which are put to work in wastewater treatment and deodorizing processes—that contribute to environmental betterment.

In 2006, the company acquired the international standard ISO 14000 certification for environmental management systems, and our commitment to competent, proper environmental management under the environmental principles set out below is ongoing.

Environmental Principles

AION Co., Ltd. as a pioneer of PVA sponges contributes to society through the provision of products esteemed by customers throughout the world, and at the same time promotes the following ongoing environmental actions.

- Comply with laws, regulations and other dictates involving the company's business activities, and work to prevent pollution and reduce the burden on the environment.

- Toward building a society modeled on resource recycling, work to curtail wastes and make sound use of resources by utilizing the Three R's.

- Recognizing the gravity of global environmental issues, implement measures to conserve resources and energy.

- With a consciousness that the prevention of environmental pollution is a corporate social responsibility, work to curtail the volume of chemical substances used and the volume discharged.

- Treating concern for the environment as a fundament of conduct, strive to make the environmental principles thoroughly known to all employees, and promote ongoing betterment actions.

Toshiyuki Konishi

Representative Director

AION Co., Ltd.

Boiler Conversion to Gas

The company is committed to further lessening CO2 and wastes emitted in our manufacturing operations, and to running cleaner. As one such commitment, on the occasion of circumstances coming together that allowed the company to utilize municipal gas, in 2015, for our industrial boiler that produces steam employed in production and heating, we traded out our boiler that ran on fuel oil for a high-combustion-efficiency natural-gas boiler.

The company is committed to further lessening CO2 and wastes emitted in our manufacturing operations, and to running cleaner. As one such commitment, on the occasion of circumstances coming together that allowed the company to utilize municipal gas, in 2015, for our industrial boiler that produces steam employed in production and heating, we traded out our boiler that ran on fuel oil for a high-combustion-efficiency natural-gas boiler.

Story and Objectives behind Boiler Conversion to Gas

At the company's factories, steam is employed as a heat source for industrial production and heating, with the steam being created in, and the necessary volume supplied by, an industrial boiler. To date, a boiler that ran on Bunker A fuel oil had been employed.

At the company's factories, steam is employed as a heat source for industrial production and heating, with the steam being created in, and the necessary volume supplied by, an industrial boiler. To date, a boiler that ran on Bunker A fuel oil had been employed.

The problem with this Bunker A fuel oil that the company was using is significant toxic atmospheric pollutants, including sulfur oxides (SOx), nitrogen oxides (NOx), and CO2. So, given that circumstances allowing the company to utilize municipal gas came together, from the perspectives of both environmental preservation and economizing on energy, the switch to a natural-gas boiler was made.

Effect of Boiler Conversion to Gas

The fact that natural-gas boilers discharge less CO2 than fuel-oil boilers and produce steam efficiently has made it possible to curtail CO2 emissions by approximately 25% annually.

The fact that natural-gas boilers discharge less CO2 than fuel-oil boilers and produce steam efficiently has made it possible to curtail CO2 emissions by approximately 25% annually.

Wastewater Treatment Facilities at Aion

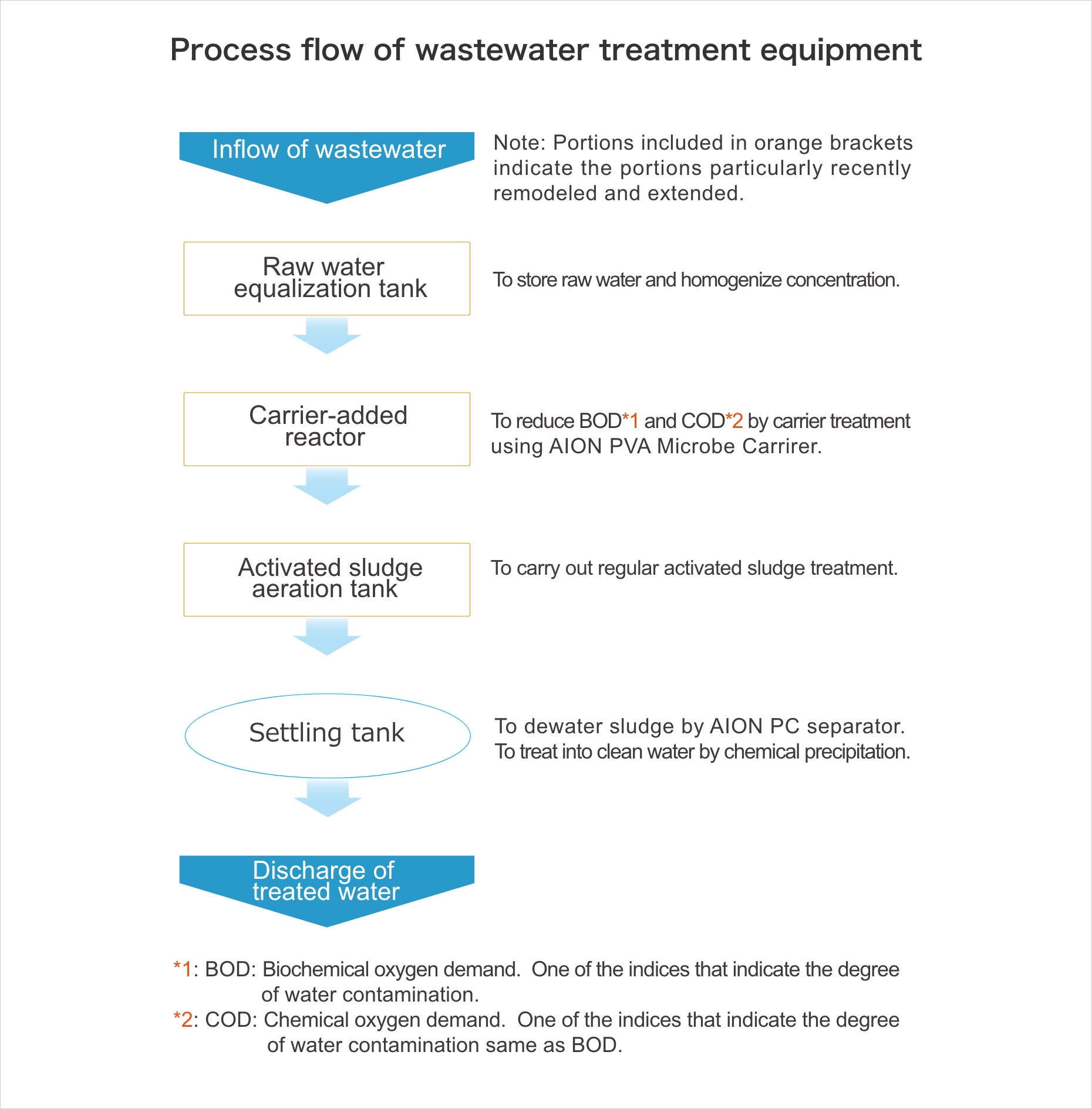

At wastewater treatment facilities, utilizing the following two environmental technologies that are the pride of the company, we are realizing advanced wastewater treatment performance.

At wastewater treatment facilities, utilizing the following two environmental technologies that are the pride of the company, we are realizing advanced wastewater treatment performance.

(1) Microorganism-Anchoring Bed: Aion PVA Microbe Carriers

(2) Sludge Dewatering Machine (Precision Solid–Liquid Separator): Aion PC Separator

Use Example (1) : Microorganism-Anchoring Supports: AION PVA Microbe Carriers

We are using the company's PVA Microbe Carriers in a carrier-casting tank filled with the microorganism-anchoring supports. The AION PVA Microbe Carriers we are using are cubes 4-mm square, in the interiors of which microorganisms are fixed, which through biological processes serve to reduce BOD and COD components. The proven outcome is that the processes have realized a fifty-percent or greater reduction by both BOD and COD components.

We are using the company's PVA Microbe Carriers in a carrier-casting tank filled with the microorganism-anchoring supports. The AION PVA Microbe Carriers we are using are cubes 4-mm square, in the interiors of which microorganisms are fixed, which through biological processes serve to reduce BOD and COD components. The proven outcome is that the processes have realized a fifty-percent or greater reduction by both BOD and COD components.

AION PVA Microbe Carriers Processing Efficiency Test

Within the wastewater treatment facilities at the company, we are carrying out processing efficiency tests on our PVA Microbe Carriers.

Within the wastewater treatment facilities at the company, we are carrying out processing efficiency tests on our PVA Microbe Carriers.

That means that raw wastewater at the company is the testing basis: With sensors for the ORP value, the oxidation–reduction potential, and the DO value, which gauges the amount of oxygen, in place and by digitizing the values, we're surveying data on the company's PVA Microbe Carriers and accumulating foundational data in order to offer business solutions to our customers.

Use Example (2) : Sludge Dewatering Machine (Precision Solid–Liquid Separator): AION PC Separator

The company's PC Separators are utilized in processes whereby sludge is drawn out from a settling tank and dewatered.

The company's PC Separators are utilized in processes whereby sludge is drawn out from a settling tank and dewatered.

The apparatuses are vacuum-filtration solid–liquid separators, and for the processes six machines have been installed and are employed in automatic operation mode.

Process Flow in Wastewater Treatment Installation

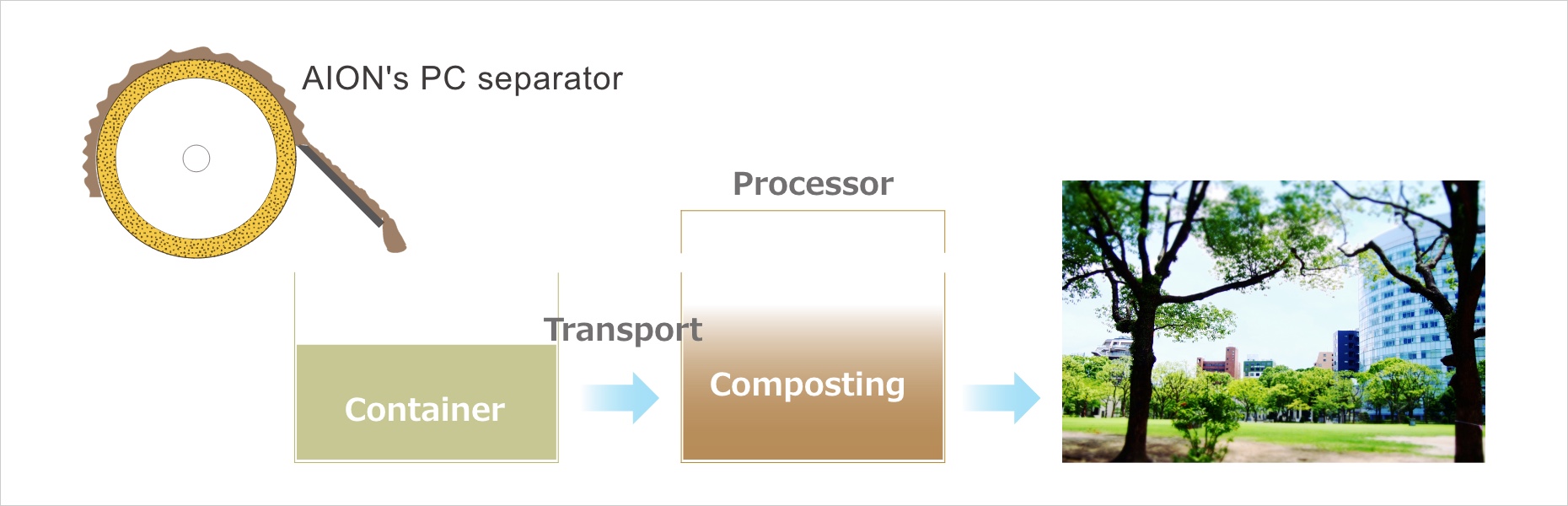

Sludge Recycling

In wastewater treatment, the processing of sludge is where the greatest challenges arise. At Aion the entire volume of sludge is composted (converted into fertilizer) and recycled through outsourcing.

The drawn-out sludge is put into containers and hauled to processing professionals, where it goes through fermentation processes, turning into compost. The applications for the compost include as soil-bettering media and greening materials.

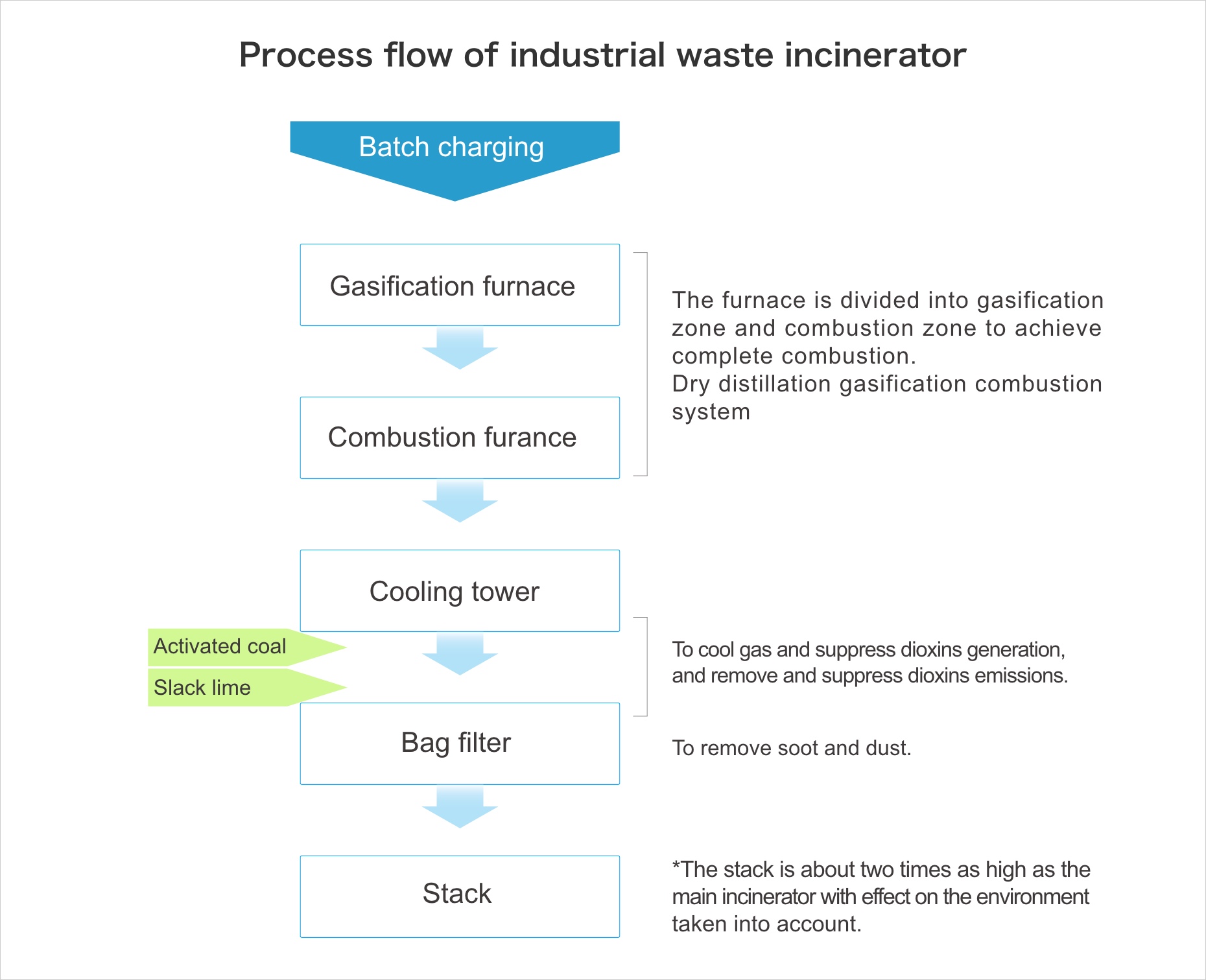

Industrial Waste Incinerator Installation

Concerning the major industry wastes generated at the company itself, assuming responsibility and creating a system that allows in-house disposal is something we take to be fundamental. Therefore, we introduced an incineration installation that complies with the express legal measures for dealing with dioxins.

Concerning the major industry wastes generated at the company itself, assuming responsibility and creating a system that allows in-house disposal is something we take to be fundamental. Therefore, we introduced an incineration installation that complies with the express legal measures for dealing with dioxins.

Example of Industrial Waste Incinerator Installation Put into Practice

The company's installation turned out to be Completion No. 1 for Ibaraki Prefecture Western District in-house disposal incineration equipment after the express legal measures came into force.

Principal Effects of Industrial Waste Incinerator Installation

Compared with conventional furnaces, the company's installation was able to reduce the generation of dioxins by 80% or more (exhaust gas and cinders together), controlling generation to one-tenth or less of the regulatory level for emissions.

Process Flow in Industrial Waste Incinerator Installation

Search by application or purpose

Search by application or purpose