The connection between AION's products and the things around us

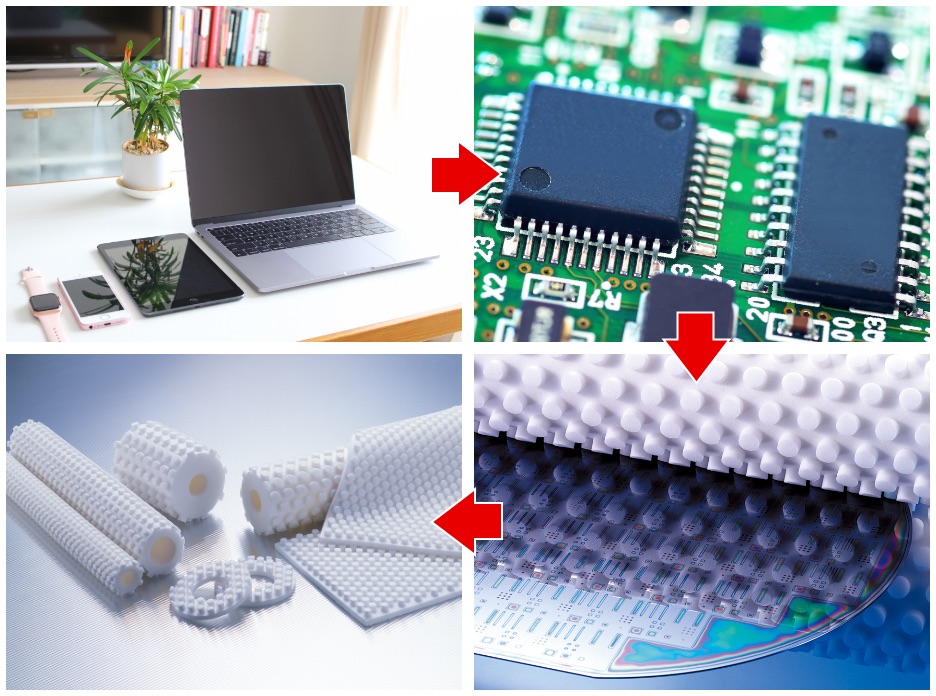

1. Smartphones and PCs, and Aion Brush Rollers

Smartphones and PCs, and AION Brush Rollers: Ever-evolving day-to-day. What holds the reins on their performance is CPUs, memories, cameras, etc.

Smartphones and PCs, and AION Brush Rollers: Ever-evolving day-to-day. What holds the reins on their performance is CPUs, memories, cameras, etc.

The component material forming the base in each case is silicon. When silicon is made into wafers (discs), and in subsequent device fabrication operations, foreign matter is near zero, and not even a scratch is tolerated.

The fabrication operations involve numerous cleaning processes; employed in these processes are AION Brush Rollers, which boast high quality.

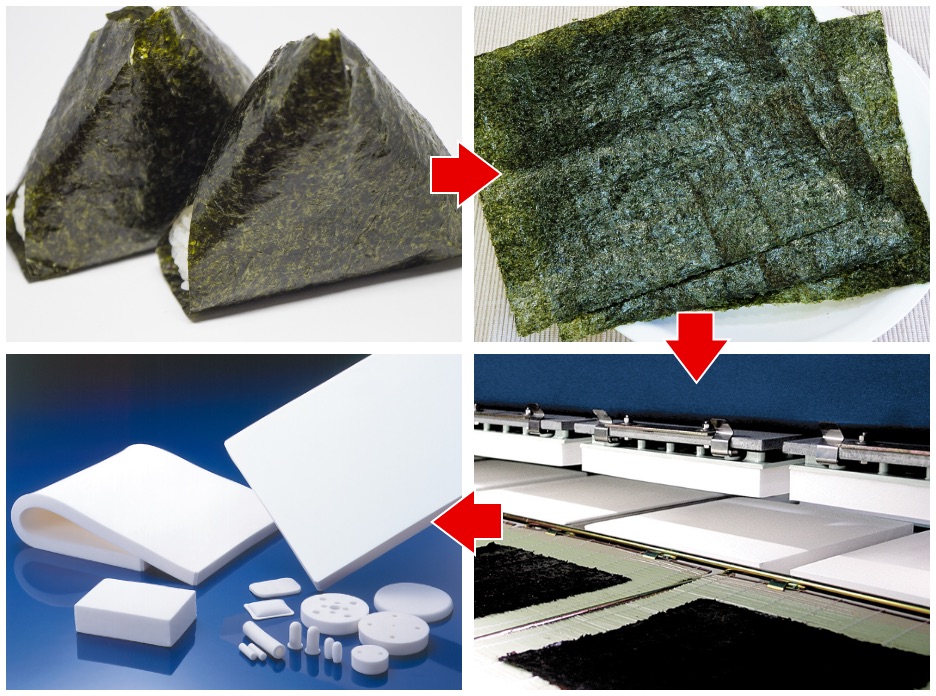

2.Onigiri and D- and W-Series Aion Sponges

In the past, all nori was made by drying seaweed in the sun.

In the past, all nori was made by drying seaweed in the sun.

Nowadays, mechanization enables mass-production of nori.

However, drying in shorter times means raising the temperature, which mars the flavor of the nori.

That being the case, the idea came about that if prior to drying, the major portion of the moisture contained in the nori was removed, the nori could be dried at low temperatures and in short times, such that its flavor would not be harmed. With this thinking, our (at the time, Kanebo Ltd.) PVA sponges came into play. AION's PVA sponges have been used for many years in nori-drying operations.

3. PCs and Data Centers, and AION PVA Grinding Stones

PCs and Data Centers, and AION PVA Grinding Stones

PCs and Data Centers, and AION PVA Grinding Stones

Indispensable for modern business and daily life: Computers and the Internet.

There, enormous volumes of data are produced and stored day-to-day.

Used to record these huge volumes of data are hard disks.

Aluminum disks are used to record the data, and the thickness and flatness of the surface demand accuracy of the highest order of magnitude. Realizing this accuracy are Aion's polishing media, "Aion PVA Grinding Stones."

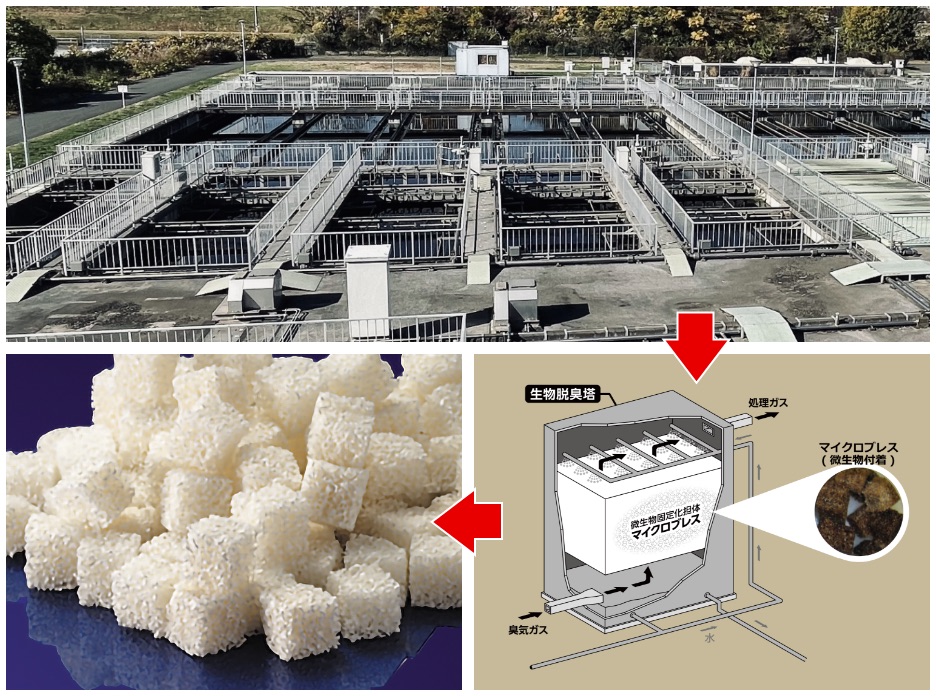

4. Environmental cleansing (deodorizing) and Aion PVA Microbe Carriers

Environmental cleansing (deodorizing) and AION PVA Microbe Carriers: In wastewater treatment, processes exploiting the powers of microorganism-based decomposition and removal are carried out, wherein to enhance the treating capacity, microbial carriers are employed. With their base being PVA sponge, which is hydrophilic and has a three-dimensional reticulated structure, AION PVA Microbe Carriers realize outstanding microbial adhesion, excel in durability, and are not decomposed by microorganisms, thanks to which the carriers are long-term usable.

Environmental cleansing (deodorizing) and AION PVA Microbe Carriers: In wastewater treatment, processes exploiting the powers of microorganism-based decomposition and removal are carried out, wherein to enhance the treating capacity, microbial carriers are employed. With their base being PVA sponge, which is hydrophilic and has a three-dimensional reticulated structure, AION PVA Microbe Carriers realize outstanding microbial adhesion, excel in durability, and are not decomposed by microorganisms, thanks to which the carriers are long-term usable.

As microorganism carriers, AION PVA products have a proven track record of contributing to environmental cleansing for more than 20 years.

5. In-vitro Diagnostic Reagents and A- and D-Series AION sponges, AION Polyurethane Sponges

In-vitro Diagnostic Reagents and A- and D-Series AION sponges, AION Polyurethane Sponges

In-vitro Diagnostic Reagents and A- and D-Series AION sponges, AION Polyurethane Sponges

In tests for influenza and other infectious diseases caused by bacteria and viruses, rapid diagnostic kits with pharmaceuticals for in-vitro diagnostics are employed. The kits are engineered for collecting a specimen, making the specimen into extract to be dripped, and determining the presence of infection depending on lines that appear from the extract being dripped onto a test section.

AION A- and D-Series Sponges and AION Polyurethane Sponges have been adopted as filters for the extract and as the component material within the test section.

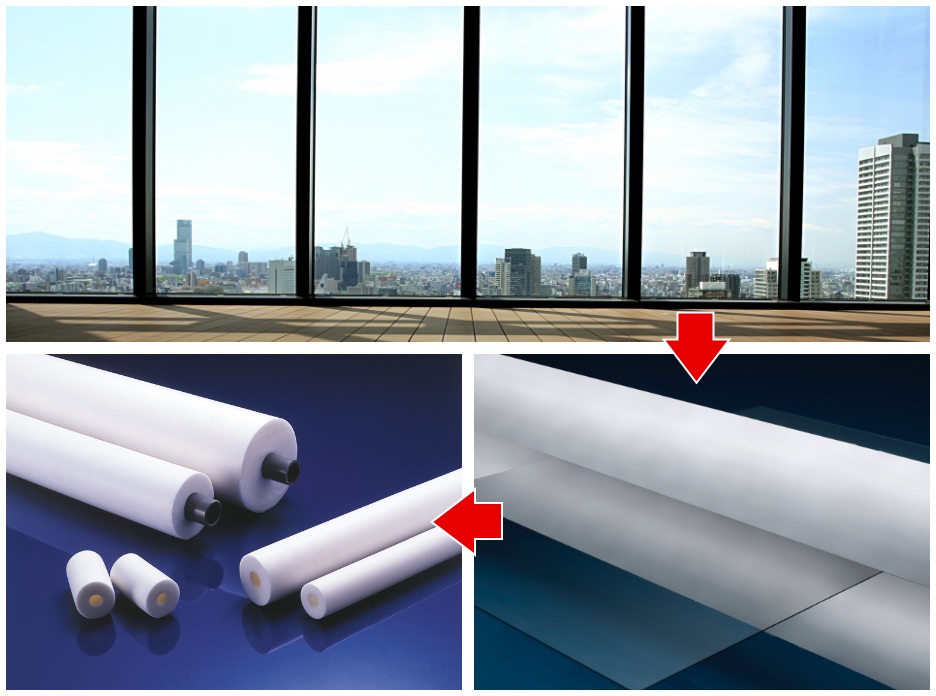

6. Window Glass and AION PVA Sponge Rollers

Window Glass and AION PVA Sponge Rollers : An elemental material that has been used since ancient times, glass is an indispensable part of our modern lives—in buildings, in homes, in car windows.

Window Glass and AION PVA Sponge Rollers : An elemental material that has been used since ancient times, glass is an indispensable part of our modern lives—in buildings, in homes, in car windows.

AION's water-absorbing sponge roller, the "AION PVA Sponge Roller," is employed following the stage of manufacturing the plate-glass large-scale stock material known as ribbon sheet—when the glass is processed into various sizes—as a water-absorbing medium after the glass is washed with water and prior to being dried, and has been used for many years with the objective of saving labor and energy and improving the work environment.

Search by application or purpose

Search by application or purpose