Types and Properties of Our Materials

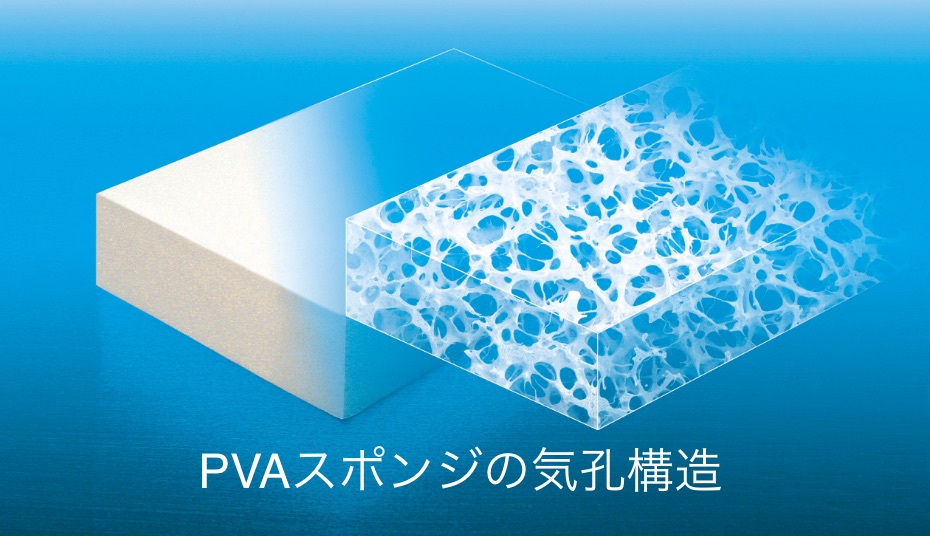

Ordinary sponges present all around us are principally manufactured by chemical foaming schemes, which produce structures in which the pores are independent of each other. In contrast, at AION, by adopting an "extraction method"—an original manufacturing scheme—we are advancing product development in the form of sponges characterized by an open-cell structure, in which the cells are joined in a reticulated configuration.

Ordinary sponges present all around us are principally manufactured by chemical foaming schemes, which produce structures in which the pores are independent of each other. In contrast, at AION, by adopting an "extraction method"—an original manufacturing scheme—we are advancing product development in the form of sponges characterized by an open-cell structure, in which the cells are joined in a reticulated configuration.

And with our technology for forming open-cell structures as the basis, we further have adjusted the cell diameter and applied our sponges to various substrate materials. In addition, through our technology for compounding our sponges with other functional media such as polishing media and thermosetting resin polymers, we have endeavored to meet exacting needs: While liquid management is the core application for our sponges, they are also utilized as advanced-functioning component materials in niche markets, reaching to structure- and characteristic-exploiting specialized applications.

Functions (keywords)

1. moisture wicking, liquid absorption 2. fluid application (water feeding, liquid feeding) 3. cleaning 4. water retention (sorbent storage, impregnation) 6. wipe-up 7. conveyance 8. filtration 9. sound attenuation 10. polishing 11. carriers (deodorization, waste-liquid treatment)

Charged with meeting multifarious demands while having our proprietary manufacturing approaches be the core, AION is taking on the challenge of new development, through tailorable ideas that go beyond preformulated general concepts—not to mention the application to date of our accumulated technology.

PVA Sponge

Polyvinyl Alcohol-Based Sponges Material: Polyvinyl formal (PVFM) resin

Sponges whose chief source material is a highly hydrophilic polyvinyl alcohol (PVA) resin.

Sponges whose chief source material is a highly hydrophilic polyvinyl alcohol (PVA) resin.

In our lineup of PVA sponges are the following three types, according to the cross-linking density control and use of resin.

Low cross-linking density polyvinyl formals products

(Product Names: D-Series Aion Sponges, Aion PVA Wiping Materials, Aion PVA Sponge Rollers, Aion Brush Rollers, Aion PVA Microbe Carriers—Soft Model, Plas Senu, Water-Drop Wiping & Absorbing Sponge Cloths, Super Moisture-Absorbing Sponges)

・Have excellent moisture absorbing ability and suppleness/elasticity in the water-containing state; Used as moisture-absorbing media, washing media, cleaning media, and cosmetics media.

・Have excellent moisture absorbing ability and suppleness/elasticity in the water-containing state; Used as moisture-absorbing media, washing media, cleaning media, and cosmetics media.

・Harden with shrinkage when dried, but soften again when water-saturated.

・Product modes available: Wet products in a moisture-containing state (soft) and dry products in a dried state (stiffened).

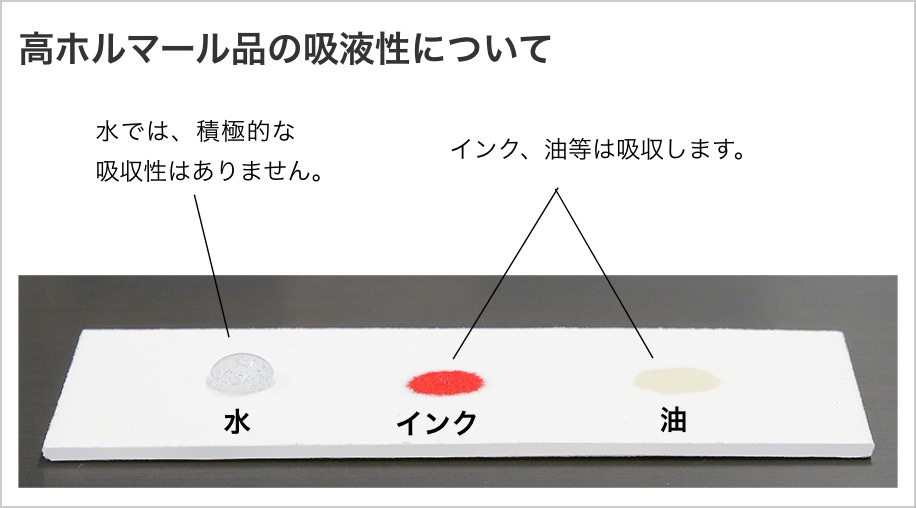

High cross-linking density polyvinyl formals products

(Product Names: A-Series Aion Sponges; Aion PVA Microbe Carriers—Hard Model)

・When in contact with water do not actively absorb liquid and do not soften.

・When in contact with water do not actively absorb liquid and do not soften.

・Employed in air and liquid filters, as well as in absorbents and sorbent storage articles for oils and inks, putting their microfine open cells to work.

Resin-Treated Products

(Product Names: PVA Sponge Filters, Micro-Lite, Aion PVA Grinding Stones/Buffs)

・Hard models in which PVA and thermosetting resins (such as melamine resins or phenol resins) are compounded.

・Hard models in which PVA and thermosetting resins (such as melamine resins or phenol resins) are compounded.

・With superior dimensional stability and chemical resistance compared with the two models described above, employed as cartridge filters for liquids, as polishing media, and as filtering media for solid-liquid separation.

PU Sponges

Polyurethane Sponges (Product Name: AION Polyurethane Sponges)

Material: Special polyurethane (PU) resin

Made of special polyurethanes that are hydrophilic, AION polyurethane sponges have minutely fine pore structures. In either the dry or wet state, they demonstrate a soft texture, exceling in moisture absorbance and liquid retentiveness.

・Excel in ability to form-follow the work, thanks to their supple elasticity.

・Usable in high temperature environments (dry/wet heat) of 100°C or more.

・For aqueous solutions containing salts, the character of our polyurethane sponges is stable, and they have resistance to alcohols and acids as well.

・The sponges' outstanding wear resistance contributes to prolonging their service life.

・In addition to variations in hardness and cell size, this line of sponges contains an assortment of models with electroconductive, antibacterial, and other functionality.

PO Sponges

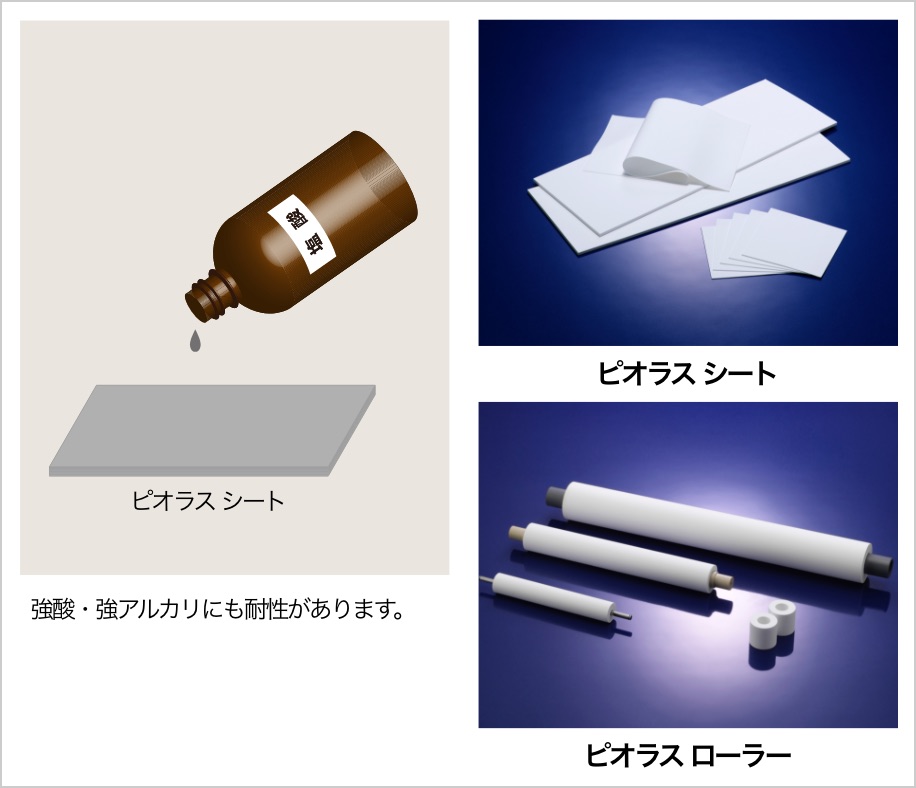

Polyolefin Sponges (Product Name: Aion Polyolefine Sponge Rollers and Sheets)

In addition to their outstanding liquid absorbance, these sponges excel in chemical resistance, and possess resistance to strong acids and bases. In our polyolefin sponge lineup are the following four kinds, whose characters differ according to the type of component materials.

In addition to their outstanding liquid absorbance, these sponges excel in chemical resistance, and possess resistance to strong acids and bases. In our polyolefin sponge lineup are the following four kinds, whose characters differ according to the type of component materials.

- PE Model: in the form of slightly firm sheets

*Material: polyethylene resin - EVA Model: in the form of slightly elastic sheets

*Material: ethylene/vinyl acetate copolymer - T Model: in the form of rollers having pliant elasticity

*Material: polyolefin elastomer resin - R Model: in the form of rollers that in addition to their pliant elasticity are free of added plasticizer

* Material: polyolefin elastomer resin

Fluorine-Based Sponges

Special fluoroplastic sponges (Product name: Aion Fliorine Rollers)

Special fluoroplastic sponges (Product name: AION Fliorine Rollers):AION's unique compounding of special fluoroplastics produces reticulated-foam articles possessing both the characteristics of fluoropolymers and a pliant elasticity. Because Fliorine Rollers do not contain the crosslinkers, stabilizers, and other additives contained in general fluoroelastomers, they are distinguished by minimal contamination risk.

Special fluoroplastic sponges (Product name: AION Fliorine Rollers):AION's unique compounding of special fluoroplastics produces reticulated-foam articles possessing both the characteristics of fluoropolymers and a pliant elasticity. Because Fliorine Rollers do not contain the crosslinkers, stabilizers, and other additives contained in general fluoroelastomers, they are distinguished by minimal contamination risk.

・Fliorine Rollers maintain, in addition to resistance to strong acids/strong bases and oxidants, a stabilized character even in harsh environments such as where there is exposure to UV and radiation.

Search by application or purpose

Search by application or purpose