When work undergoes wet-etching processes, etchant cannot be done without. However, given their characteristic corrosive action, etchants come with their hazards, which mandates care in their handling. Here we introduce the hazards of etchants, methods of their disposal, and precautions for their handling.

In the wet etching of printed circuit boards, etchants of several types are employed. Those that require care in handling are many, and if such etchants are not strictly managed, they may have an adverse effect on workers’ health and on the environment. In this article we will introduce the categories of etchants and precautions for their handling.

Etchants Indispensable in Wet Etching

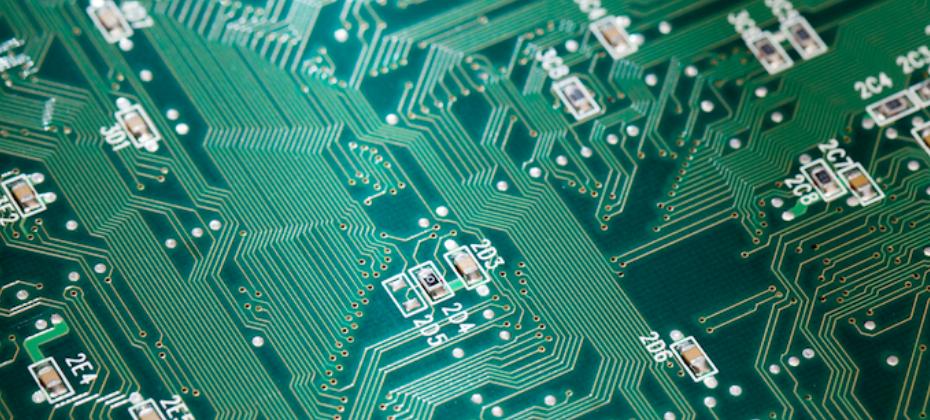

Etching, processing technology that puts corrosive action to practical use, includes wet etching, in which the processing is carried out utilizing solutions, and dry etching, in which the processing is carried out utilizing gases. These forms of etching, which is also referred to as chemical milling, are employed for the copper-foil based creation of printed circuit boards and semiconductor electrical paths. Of the two, wet etching is characterized by high productivity, in that multiple sheets of material being processed may be treated at once, and by being superior in terms of cost, in that the etchants are inexpensive.

Nevertheless, care must be taken with some aspects of wet etching. Given that by its very principle, etching is a technique that processes by corroding, strong acids, strong alkalis, and strong bases are utilized as etchants. These solutions must be handled with considerable care.

The use of etchants is divided according to the properties of the substrate material being processed. For example, where etching is often exploited today is in the manufacture of printed circuit boards. In that manufacturing procedure, etching is carried out for configuring the copper foil that serves as the pathways for electricity. For such etching of copper, solutions of the following kinds are employed.

- FeCL3

ferric chloride (III) - (NH4)2S2O8

ammonium peroxodisulfate (ammonium persulfate) - CuCL2

Copper chloride(Ⅱ) - CrO3

Chromium oxide (VI)

→ Article “Etching: A Processing Method Exploiting the Corrosive Properties of Widely Used Acids”

Hazardousness of Etchants

All of the solutions employed as etchants are toxic in some way and must be handled with care.

FeCL3, for example, is widely used to etch not only copper, but also aluminum, chromium, nickel, and irons and steels, including stainless steel. The compound FeCL3 is categorized, in the safety classification for skin corrosion and irritation, as a category 1 substance, the most hazardous and toxic.

Likewise, (NH4)2S2O8, which is mainly used for etching copper, has an impact on the respiratory tract, and is characteristically prone to igniting and burning intensely if mixed with a combustible material.

CuCL2 has the potential to induce allergic dermatitis and is toxic to aquatic environments. If there were a CuCL2 spill, there would be a danger of water-quality deterioration and mass mortality of aquatic organisms taking place, ending in a major collapse of the aquatic environment.

The majority of substances utilized as etchants thus have an adverse impact on human health and the environment. For the prevention of such adverse impact and for the sake of safe operations, considerable care in handling etchants is mandatory.

Disposal Treatment of Etchants

The etchants used to etch copper foil in the stages of manufacturing printed circuit boards contain a large amount of copper ions. For this reason, they are designated as environmental contaminants that give rise to heavy-metal contamination; flushing them into the sewer system is strictly prohibited.

Heavy-metal contamination brings with it grave consequences, as is widely known from the pollution controversies in which serious harm has come about due to wastewater from copper mines. Heavy-metal contamination affects not only plants and animals inhabiting rivers, but also crops in fields and paddies irrigated via the rivers, undoubtedly leading to destruction of the aquatic environment. Also, because etchant liquid waste corrodes iron pipes and copper tubes, it is linked to facilities damage.

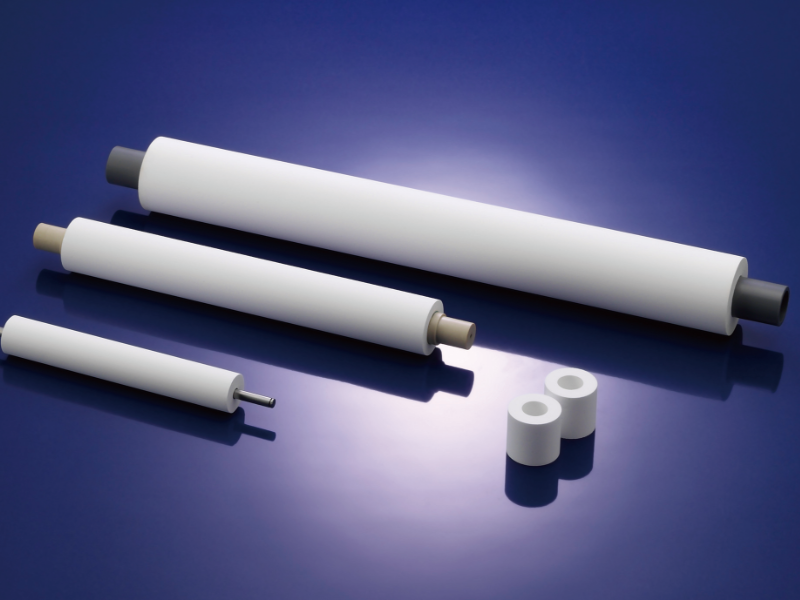

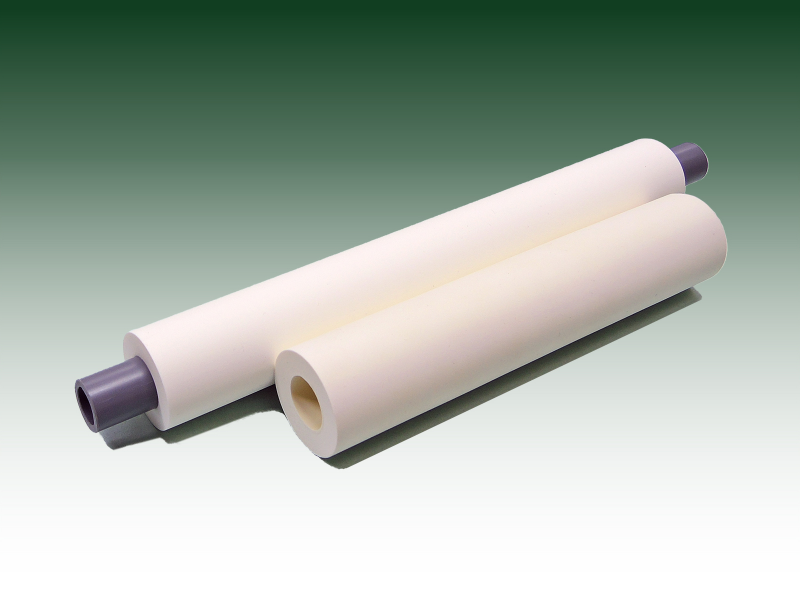

For these reasons, used etchant must be kept under strict guard and disposal-treated according to due methods. Storing and hauling away of etchants in general is carried out in non-corroding containers, the collection of which is outsourced to professional contractors who disposal-treat the etchants.

In situations, however, where a contractor is hired to dispose of etchants produced in large volume, the disposal cost is noticeable. The cost of etchant disposal in wet etching has been an ongoing issue from a productivity perspective.

To address such issues, these days etchant recycling devices are being developed. Some can recycle etchant and are capable of recovering dissolved copper, which is making etchant reuse at a high standard possible.

Precautions for Handling Etchants

As we’ve shown so far, substances that have an impact on human health and the environment are used for etchants. Consequently, for handling etchants, the work environment and facilities must be set up taking heed of the following cautions.

Use of Equipment that Takes Spill Prevention into Account

In the unlikely event that there is an etchant-waste spill, there would be a danger of contaminating the surrounding aquatic environment.

We recommend using etching equipment designed taking that there not be any etchant outflow into account, to securely prevent etchant from spilling out to the equipment exterior. Setting up on-premises drainage facilities is also necessary, so that etchant will not be flushed into the sewer system.

Maintenance of Work Environment

When etchants are utilized, the work environment must also be kept in condition to ensure workers’ safety.

Also necessary is setting up the work environment so that etchant will not get on workers’ clothes , and establishing and providing opportunities for education on safe work procedures.

Furthermore, inhalation of etchant that has turned into mist or vapor may affect the respiratory tract. Workrooms must be equipped with ventilation facilities to prevent them from becoming filled with etchant mist or vapor.

Some etchants by nature will ignite from being brought into contact with or mixed with combustible materials, some are a risk of inducing fires, and some may generate toxic gases by coming into contact with certain metals. In this regard as well, careful attention must be given to how the etchants are kept under guard and to the machinery and materials used, to set up a safe work environment.

Top-to-Bottom Wearing of Protective Gear for Job Safety

The substances employed as etchants each threaten the human body with toxicity—including skin corrosion/irritation and respiratory-tract hypersensitization. Apart from those hazards are various others including, according to type: acute toxicity by the oral route, grave injury to the eyes and eye irritation, central nervous system impairment, and systemic poisoning.

During jobs in which etchants are handled, the wearing of protective gear including goggles, face shields, facemasks, and work gloves must be obligatory; suiting up on-site must be thorough.

Moreover, not only etching workers, but also those in charge of maintaining and managing etching equipment, and those in charge of carrying out management, replenishment, and disposal of etchants, should ready the necessary protective gear to take on the challenge of top-to-bottom suiting up.

Proper Handling of Etchants for Safe Work

Here we’ve given an introduction to the objectives of utilizing the etchants employed in wet etching, to representative etchant substances, to etchant hazards and disposal methods, and to precautions in the handling of etchants.

Etching, indispensable in printed-circuit-board manufacturing operations, is a processing technique that today we cannot do without, yet the risks attributed to etchants should not be forgotten. Many of the substances employed as etchants are toxic in some way or other, and must be handled with considerable care. For the sake of structuring a safer environment in which to work, wouldn’t it be effective to provide an opportunity for managers and workers to cooperate and review once again whether an environment allowing safe and secure work is being maintained?

Search by application or purpose

Search by application or purpose